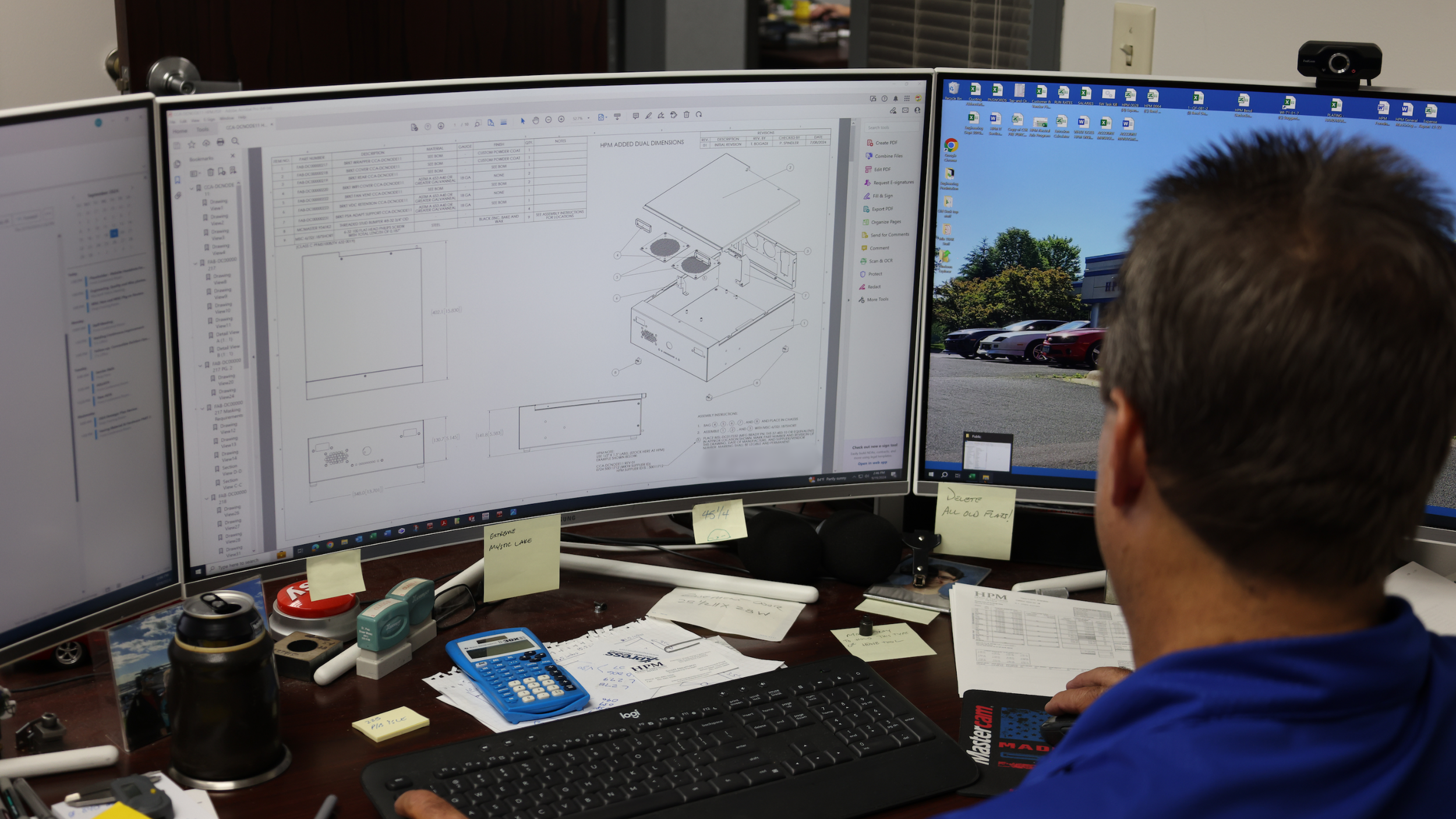

Engineering Fabrication Services for Precise, Scalable Results

From design consultation to production-ready documentation, our engineering team brings decades of experience to your parts for on-time, on-budget, and built-to-spec results. We don’t just take your files and run them through the shop. We collaborate early to reduce risks, improve manufacturability, and guide you toward the best fabrication outcome.

Design for Manufacturability Engineering Built Into Every Project

During the new product introduction (NPI) process, our engineers work closely with your team to improve designs for production success. Here’s how we support your part development:

DFM Guidance

We collaborate on features, tolerances, materials, and manufacturing questions to prevent downstream issues and reduce production costs.

Cost-Effective Tooling Recommendations

We help you select from our existing tool library for features like louvers, knockouts, wire ties, cutouts, and embosses to eliminate unnecessary tooling expenses. For new or custom tools, we provide pricing early for better budgeting.

Design Modification Support

Whether it’s switching from welding to riveting or adjusting a bend radius for tooling availability, we’ll help you refine your design without compromising function.

Forming Support

We assist with unfolding and modeling bent parts to align with our extensive press brake tooling library, supporting consistent, accurate fabrication.

Full-Service Fabrication Engineering Support

Beyond DFM, Herold Precision Metals provides full engineer-driven fabrication capabilities to support any product development stage:

Concept Development: Translate ideas or sketches into 3D CAD files

Prototyping: Rapid production and testing for fit, function, and feedback

Reverse Engineering: Model creation from physical parts or assemblies

Production-Ready Design: Final design packages prepared for scaling

Design for Assembly (DFA): Optimize parts for ease of downstream assembly

We act as an extension of your team to turn concepts into manufacturable products with performance, compliance, and production efficiency in mind.

Our Engineering Process

Documentation review and kickoff discussion

Early DFM consultation for fit, form, and function

Production method review and validation

Machine programming and fixture development

Supplemental drawing and print creation

Production optimization and cost reduction feedback

Engineering Tools, Simulation & Validation

Our team uses advanced tools and software to model, validate, and prepare your part before it ever hits the shop floor. This level of preparation helps prevent surprises and supports better production results.

CAD Modeling: We use SolidWorks to build accurate 3D parts and assembly files

AP100 Programming: Optimize tooling paths for efficiency and consistency

Finite Element Analysis (FEA): Simulate stress, deflection, and tolerance behavior

Digital Twins: Virtual models help identify design flaws early and reduce rework

Fixture Design & Programming: Plan workholding and fabrication steps with precision

Engineering Knowledge Transfer

We offer engineering knowledge transfer to help your team understand fabrication requirements, reduce unnecessary rework, and speed up approvals. Our team bridges the gap between design and production, helping both sides succeed.

Training on how to dimension prints for manufacturability

Guidance to reduce over-tolerancing that delays FAIR or PPAP

Collaborative drawing review to align expectations early

FAQs About Fabrication Engineering

-

Fabrication engineering involves the planning, modeling, testing, and preparation of parts for manufacturability. It bridges design and production to help bring parts to life accurately and efficiently.

-

Yes. We assist with PPAP and FAIR documentation through engineering collaboration, simulation, and inspection preparation. Visit our quality assurance page to learn more.

-

Absolutely. We offer reverse engineering services that involve scanning, modeling, and validating parts when original CAD files aren’t available.

-

DFM (Design for Manufacturability) focuses on how easily a part can be fabricated. DFA (Design for Assembly) focuses on how easily parts can be assembled together. We provide support for both.

-

Yes. We encourage early communication with our engineering team to validate concepts and provide initial DFM feedback, especially for new product introductions.

Learn More About Engineering

-

Design for Manufacturability: Adding Value & Reducing Costs

Learn how DFM supports better quality, faster production, and reduced costs.

-

Automate Your Flat Part Inspection and FAIR Documentation

Explore how automating inspection speeds up your launch without compromising quality.

-

Transforming Component Qualification for the Medical Industry

See how HPM collaborated closely with a medical equipment manufacturer’s engineering team to redefine their fabrication and inspection processes.