Stay Updated with the Latest in Metal Fabrication News and Industry Insights

HPM News & Blog

Find the latest fabrication news, insights from the metal fabrication industry, and updates on what’s happening at HPM.

Find what your looking for

We Think Like a Tier 1 Manufacturing Vendor Even If We’re Tier 2 in the Supply Chain

Even when listed as Tier 2 or Tier 3 on the PO, we operate with Tier 1 standards in quality, communication, and reliability for contract manufacturers.

No One Talks About the Real Cost of Revisions

There are hidden costs of design and manufacturing revisions. Learn why small changes create big headaches and how HPM helps minimize them.

Prototypes That Can’t Scale Are a Waste of Time

Many prototypes break down when it's time to scale. Learn how HPM helps bridge the gap between prototype and production with scalable, cost-effective support.

Don’t Send Us a Print. Send Us a Problem.

Stop sending prints and start solving problems. Learn how Herold Precision Metals collaborates early to troubleshoot, optimize, and manufacture with precision.

“It’s Just a Bracket” Is Why Your Project Is Late

Every complex assembly depends on the small stuff. That means even the most basic components, like brackets, stiffeners, or tabs, have the power to throw off your tolerances, disrupt your quality assurance (QA) process, and blow your budget.

Mastering Sheet Metal Assembly: 5 Essential Techniques and Applications

It’s not a one-size-fits-all process. Depending on the design requirements, material characteristics, and final application, assembly may require threaded fasteners, press-fit PEM hardware, spot welds, rivets, or a combination of joining methods.

Navigating the Labor Shortage in Metal Fabrication: Strategies for Midwest Manufacturers

The U.S. manufacturing industry continues to struggle with talent. Explore the causes of this shortage and get practical strategies, from smart design and advanced automation to effective hiring and retention, to help your business thrive.

How to Cut Sheet Metal Efficiently and Reduce Material Waste

This guide breaks down the most effective ways to cut sheet metal efficiently and how to minimize material scrap across design, planning, and production.

Automate Your Flat Part Inspection and FAIR Documentation

Automation is transforming traditional inspection workflows, turning what used to take several hours into highly accurate, data-driven reports generated in just minutes.

Riveting vs. Welding: Choosing the Right Metal Joining Method

Riveting and welding are two of the most commonly used techniques in fabrication to join metal components. Both methods create strong, permanent bonds, but they differ significantly in process, aesthetics, cost, and ideal applications. Get to know the differences.

Four Common Methods for Threading Holes in Sheet Metal

Choosing the right threading method means making sure those threads withstand real-world stress, vibration, and repeated use. Here’s a look at four of the most common methods fabricators use to create strong, reliable threaded connections in sheet metal.

Transforming Component Qualification for the Medical Industry

Top medical equipment manufacturer sought to address inefficiencies in their component qualification process, including lengthy inspections, over-dimensioned drawings, mismatched CAD models, and unclear DFM guidelines. HPM collaborated closely with medical equipment manufacturer’s engineering and quality teams to redefine their fabrication and inspection processes.

Laser Inspection for Sheet Metal: How It Works & Why It Matters

Laser scanner inspection technology has transformed how fabricators can verify accuracy so that every part meets precise dimensional standards before it moves to production or assembly. So how does laser inspection work, and why does it matter for your fabrication projects?

Choosing the Right PEM Hardware: Types & Installation Best Practices

A well-installed self-clinching fastener might never catch your attention, yet it plays a critical role in securing enclosures, panels, and components across industries. PEM hardware is an essential but often overlooked component of sheet metal fabrication.

MIG vs. TIG Welding: Understanding Both Processes

Welding is a cornerstone of metal fabrication, and choosing the right technique can make or break your project. The majority of welding projects utilize either Metal Inert Gas (MIG) or Tungsten Inert Gas (TIG) welding. Which method is right for your specific needs?

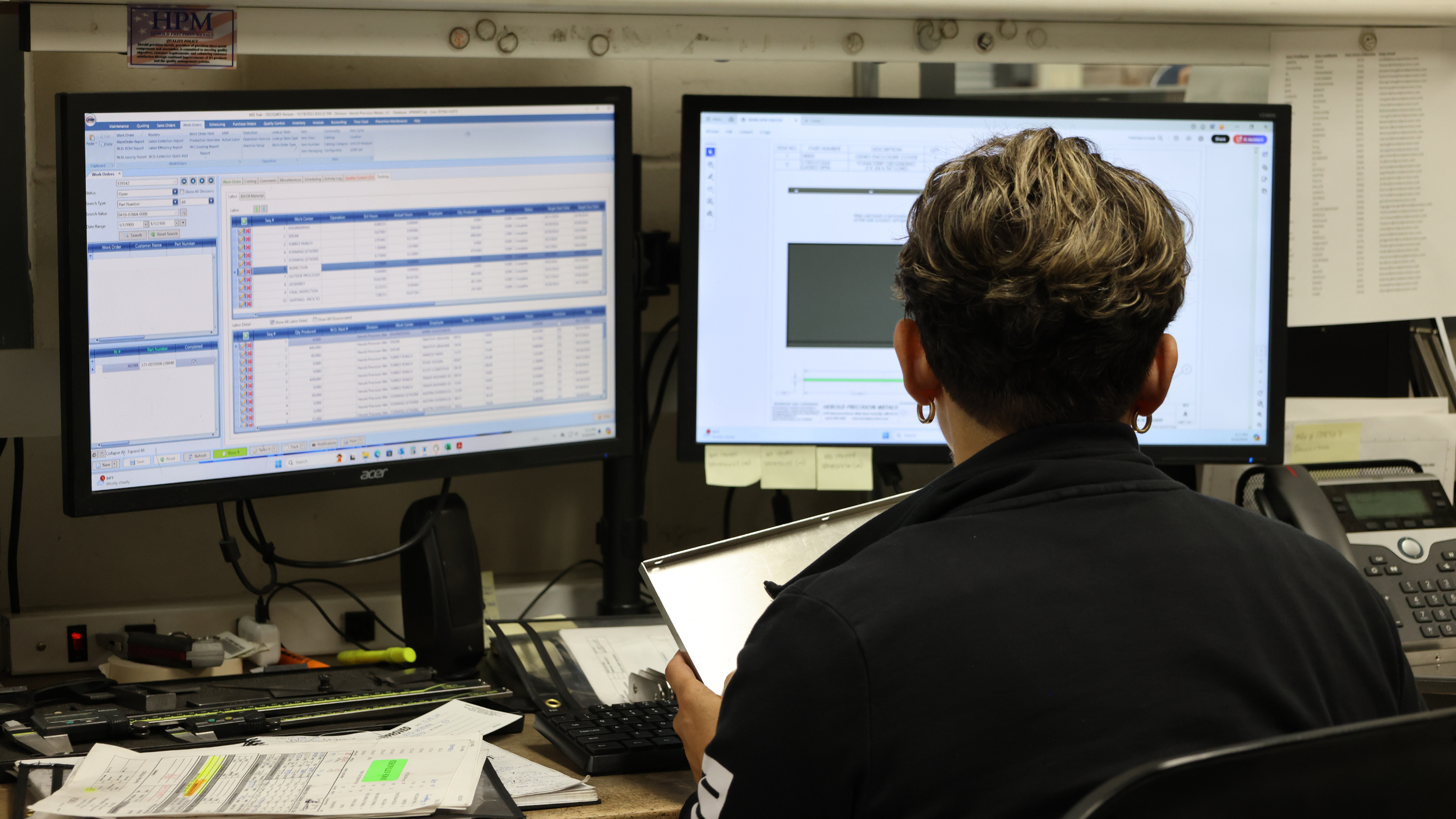

The Benefits of Managed Inventory: Focus on Growth, Not Stock

HPM offers warehousing and managed inventory solutions designed to keep your production running efficiently. We don’t just fabricate precision metal components — we provide end-to-end inventory solutions that streamline your supply chain.

Panel Bending vs. Press Brake Forming: Choosing the Right Method for Your Project

In this guide, we’ll break down the technical aspects of these two methods, their strengths and limitations, and how to determine the best fit for your project. By the end, you’ll know which process offers the precision and efficiency you need to deliver high-quality results.

Design for Manufacturability: Adding Value & Reducing Costs

DFM is more than a service — it’s a cornerstone of how we approach every project. By integrating engineering expertise with advanced manufacturing capabilities, we help clients optimize their designs, reduce costs, and improve efficiency without sacrificing quality. We’ll explore how DFM can help your business reduce costs, improve efficiency, and enhance product value — all while maintaining quality.

Sheet Metal Tolerances Explained: Achieving Precision in Fabrication

Achieving the correct sheet metal tolerances is crucial for balancing precision, cost, and performance. By collaborating early with engineers, focusing on functional features, and keeping CAD models up-to-date, you can avoid unnecessary complexity and ensure high-quality, cost-effective results.

Sheet Metal 101: Essential Terms & Concepts Every Engineer Should Know

This guide bridges the gap between traditional fabrication methods and cutting-edge digital technologies, breaking down the concepts that matter most, from the crucial Pack and Go process for keeping your computer-aided design (CAD) files intact, to the laser scanning technology revolutionizing quality control.

Stay Informed with HPM News Today!

Don’t miss out on the latest updates and insights from the metal fabrication industry. Subscribe to our newsletter to get the newest articles delivered straight to your inbox.